Forged with Care

The razor’s manufacturing begins with the forging of stainless steel, where the handle takes shape under high pressure to enhance strength and durability. It is then CNC-machined to meet tight tolerances and ensure accurate component alignment.

Forged with Care

The razor’s manufacturing begins with the forging of stainless steel, where the handle takes shape under high pressure to enhance strength and durability. It is then CNC-machined to meet tight tolerances and ensure accurate component alignment.

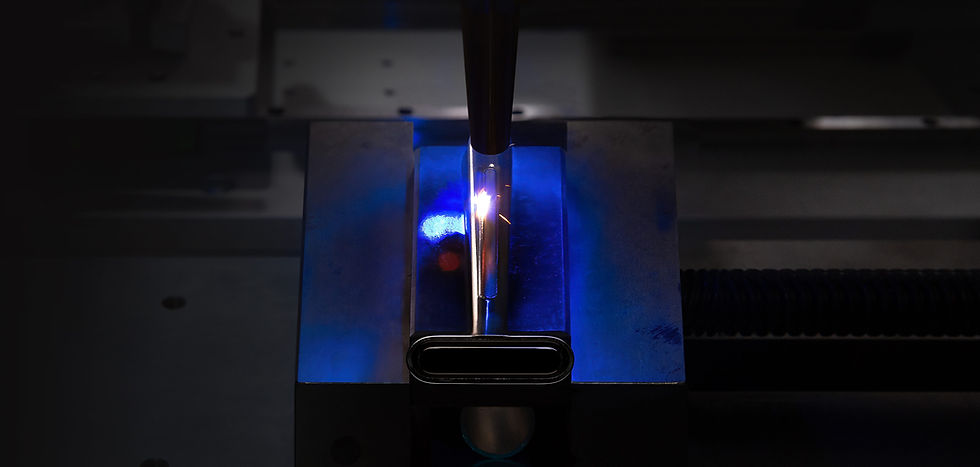

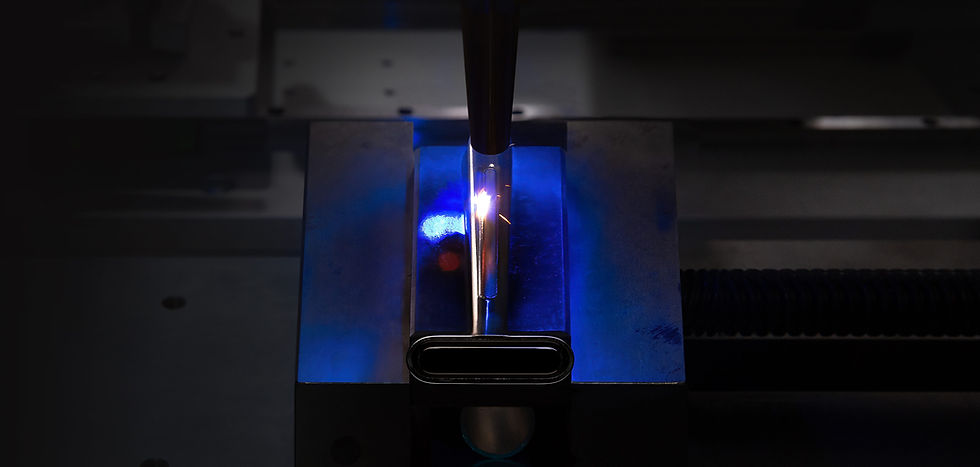

Engineered as One

SUS 316L and SUS 630 stainless steels are laser-welded, forming a handle structure that is both ferromagnetic and highly corrosion resistant. Inside the head, custom micro-scale Halbach array magnets receive a solid film coating. They are then sealed behind a 316L stainless cover plate with a silicone gasket.

Finished by Hand

Each razor is polished to a mirror finish before receiving a PVD coating. This process refines the surface, enhances cleanability, and gives the piece a sculptural presence within its environment.

Precision Blades

We utilize high-grade stainless steel blades coated in platinum to extend their lifespan. Cartridges are inspected under magnification to ensure edge quality and consistency, delivering a shave that feels clean, comfortable, and reliable.

Seamlessly Engineered

Razor blades are enclosed between an insert-molded top half and a triple-injection-molded bottom half. The two halves are then ultrasonically welded together, creating an exceptionally robust assembly.

Considered Materials

At MECO, material choices are guided by longevity and environmental care. The handle is formed in stainless steel for lasting use, while cartridges incorporate recycled plastics. Packaging is deliberately minimal, relying on essential paper elements to reduce impact.